- Flow Regulation: The primary purpose of a slide gate valve is to regulate the flow of water. By opening or closing the gate, the operator can control the amount of water that passes through the system.

- Isolation: These valves can act as an isolation mechanism, allowing the shutdown of specific sections of the treatment or distribution system for maintenance, repairs, or emergencies.

- Level Control in Reservoirs and Basins: In water treatment plants, certain processes require maintaining water at specific levels in tanks, basins, or reservoirs. Slide gate valves can control these levels by adjusting the flow in or out.

- Backflow Prevention: In some configurations, slide gate valves prevent backflow, protecting treated water from potential contamination.

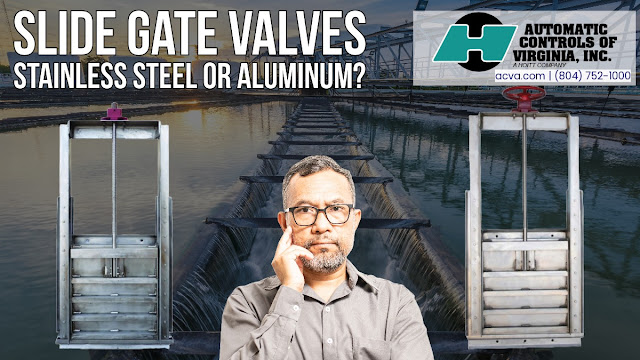

Next, let's look into the construction and application differences between aluminum and stainless steel slide gate valves:

Aluminum Slide Gate Valves:

- Lightweight: Aluminum is less dense than stainless steel, making aluminum slide gate valves relatively light, simplifying installation, particularly in scenarios where weight can be a limiting factor.

- Corrosion Resistance: Aluminum forms a protective oxide layer naturally when exposed to air, giving it a degree of corrosion resistance. However, it may be more susceptible to corrosion in specific environments than stainless steel, especially in saline or highly alkaline conditions.

- Cost-Effective: Aluminum slide gate valves are generally less expensive than their stainless steel counterparts.

Stainless Steel Slide Gate Valves:

- Strength: Stainless steel is more robust than aluminum, allowing these valves to handle higher pressures and stresses.

- High Corrosion Resistance: Stainless steel's corrosion resistance is greater than aluminum's, particularly when the material is exposed to aggressive chemicals or saline environments.

- Durability: Due to its strength and resistance to corrosion, stainless steel slide gate valves tend to have a longer service life than aluminum valves, especially in challenging conditions.

- Higher Cost: Stainless steel materials generally cost more than aluminum, leading to a higher price point for these slide gate valves.

Aluminum Slide Gate Valve Application:

- General Water Treatment: Suitable for standard water treatment applications where the water's pH and salinity do not pose significant corrosion risks.

- Distribution Systems: Useful in systems where lightweight components are preferred for ease of installation or maintenance.

- Stormwater Management: Employed in systems that don't expose the valve to particularly aggressive conditions.

Stainless Steel Slide Gate Valve Applications:

- Wastewater Treatment: Particularly effective in wastewater treatment plants where the water might contain a range of chemicals, which can be corrosive.

- Desalination Plants: Given the saline nature of the input water, stainless steel's superior resistance to salt-induced corrosion makes it the material of choice in desalination facilities.

- Chemical Dosing Areas: In sections of water treatment facilities where chemicals are added, stainless steel valves can better resist potential chemical corrosion.

- High-Pressure Scenarios: Due to their strength, stainless steel slide gate valves are suitable for applications requiring the handling of high pressures.

While aluminum and stainless steel slide gate valves have their merits, the choice between them often boils down to the application's specific needs and the environment in which the valve will operate. Careful consideration of factors like corrosion potential, pressure requirements, and budget constraints will help select the most suitable material for a given setting in the water industry. Automatic Controls of Virginia offers expert guidance in selecting the optimal material for your specific valve application. Numerous businesses rely on their proven engineering methodologies and extensive experience in the valve industry, ensuring a technically sound and efficient valve solution for your operational needs.

Automatic Controls of Virginia

https://acva.com

(804) 752-1000